| [1] |

赵婷婷, 范立坤, 黎阳. 陶瓷材料抗热震性的研究进展[J]. 机械工程材料, 2022, 46(12): 1-8. doi: 10.11973/jxgccl202212001ZHAO Tingting, FAN Likun, LI Yang. Research progress on thermal shock resistance of ceramic materials[J]. Materials for Mechanical Engineering, 2022, 46(12): 1-8. (in Chinese) doi: 10.11973/jxgccl202212001

|

| [2] |

李鸿鹏, 凌松, 戚振彪, 等. 热力耦合问题数学均匀化方法的计算精度[J]. 应用数学和力学, 2020, 41(1): 54-69. doi: 10.21656/1000-0887.400119LI Hongpeng, LING Song, QI Zhenbiao, et al. Accuracy of the mathematical homogenization method for thermomechanical problems[J]. Applied Mathematics and Mechanics, 2020, 41(1): 54-69. (in Chinese) doi: 10.21656/1000-0887.400119

|

| [3] |

李若愚, 王天宏. 薄板热力耦合的屈曲分析[J]. 应用数学和力学, 2020, 41(8): 877-886. doi: 10.21656/1000-0887.400308LI Ruoyu, WANG Tianhong. Thermo-mechanical buckling analysis of thin plates[J]. Applied Mathematics and Mechanics, 2020, 41(8): 877-886. (in Chinese) doi: 10.21656/1000-0887.400308

|

| [4] |

杨国欣, 郑世风, 李定玉, 等. 考虑损伤判据温度相关性的相场法模拟氧化铝热冲击裂纹扩展[J]. 应用数学和力学, 2022, 43(11): 1259-1267.YANG Guoxin, ZHENG Shifeng, LI Dingyu, et al. Thermal shock crack propagation of alumina simulated with the phase-field method under temperature-dependent damage criteria[J]. Applied Mathematics and Mechanics, 2022, 43(11): 1259-1267. (in Chinese)

|

| [5] |

马玉娥, 陈鹏程, 郭雯, 等. 基于光滑有限元法的热-弹相场断裂研究[J]. 固体力学学报, 2023, 44(3): 346-354.MA Yu'e, CHEN Pengcheng, GUO Wen, et al. Stady on thermo-elastic phase fracture modeling based on the cell-based smoothed finite element method[J]. Chinese Journal of Solid Mechanics, 2023, 44(3): 346-354. (in Chinese)

|

| [6] |

SILLING S A. Reformulation of elasticity theory for discontinuities and long-range forces[J]. Journal of Mechanics Physics of Solids, 2000, 48(1): 175-209. doi: 10.1016/S0022-5096(99)00029-0

|

| [7] |

SILLING S A. Linearized theory of peridynamic states[J]. Journal of Elasticity, 2010, 99(1): 85-111. doi: 10.1007/s10659-009-9234-0

|

| [8] |

SILLING S A, EPTON M, WECKNER O. Peridynamic states and constitutive modeling[J]. Journal of Elasticity, 2007, 88(2): 151-184. doi: 10.1007/s10659-007-9125-1

|

| [9] |

BOBARU F, DUANGPANYA M. A peridynamic formulation for transient heat conduction in bodies with evolving discontinuities[J]. Journal of Computational Physics, 2012, 231(7): 2764-2785. doi: 10.1016/j.jcp.2011.12.017

|

| [10] |

BOBARU F, DUANGPANYA M. The peridynamic formulation for transient heat conduction[J]. International Journal of Heat and Mass Transfer, 2010, 53(19/20): 4047-4059.

|

| [11] |

OTERKUS S, MADENCI E, AGWAI A. Fully coupled peridynamic thermomechanics[J]. Journal of the Mechanics and Physics of Solids, 2014, 64: 1-23. doi: 10.1016/j.jmps.2013.10.011

|

| [12] |

D'ANTUONO P, MORANDINI M. Thermal shock response via weakly coupled peridynamic thermo-mechanics[J]. International Journal of Solids and Structures, 2017, 129: 74-89. doi: 10.1016/j.ijsolstr.2017.09.010

|

| [13] |

WANG Y T, ZHOU X P, ZHANG T. Size effect of thermal shock crack patterns in ceramics: insights from a nonlocal numerical approach[J]. Mechanics of Materials, 2019, 137: 103133. doi: 10.1016/j.mechmat.2019.103133

|

| [14] |

GAO Y, OTERKUS S. Ordinary state-based peridynamic modelling for fully coupled thermoelastic problems[J]. Continuum Mechanics and Thermodynamics, 2019, 31: 907-973. doi: 10.1007/s00161-018-0691-1

|

| [15] |

WANG Y T, ZHOU X P, ZHANG T. An improved coupled thermo-mechanic bond-based peridynamic model for cracking behaviors in brittle solids subjected to thermal shocks[J]. European Journal of Mechanics A: Solids, 2019, 73: 282-305. doi: 10.1016/j.euromechsol.2018.09.007

|

| [16] |

李星, 顾鑫, 夏晓舟, 等. 考虑相变的近场动力学热-力耦合模型及多孔介质冻结破坏模拟[J]. 力学学报, 2022, 54(12): 3310-3318. doi: 10.6052/0459-1879-22-521LI Xing, GU Xin, XIA Xiaozhou, et al. Peridynamic thermomechanical coupling model with phase change and simulation of freezing failure of porous media[J]. Chinese Journal of Theoretical and Applied Mechanics, 2022, 54(12): 3310-3318. (in Chinese) doi: 10.6052/0459-1879-22-521

|

| [17] |

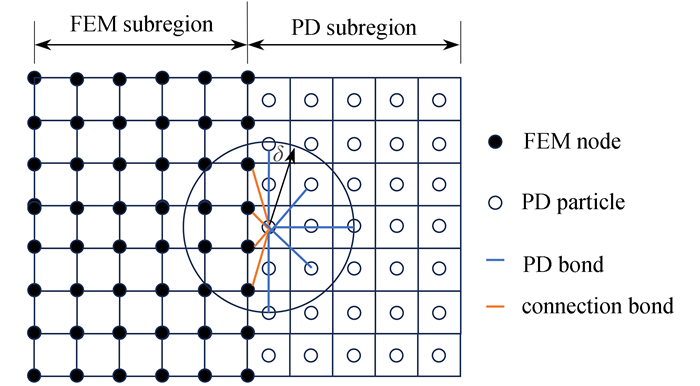

KILIC B, MADENCI E. Coupling of peridynamic theory and the finite element method[J]. Journal of Mechanics and Structures, 2010, 5(5): 707-733. doi: 10.2140/jomms.2010.5.707

|

| [18] |

LIU W Y, HONG J W. A coupling approach of discretized peridynamics with finite element method[J]. Commuter Methods in Applied Mechanics and Engineering, 2012, 245: 163-175.

|

| [19] |

SELESON P, BENDDINE S, PRUDHOMME S. A force-based coupling scheme for peridynamics and classical elasticity[J]. Computational Materials Science, 2013, 66: 34-49. doi: 10.1016/j.commatsci.2012.05.016

|

| [20] |

BIE Y H, CUI X Y, LI Z C. A coupling approach of state-based peridynamics with node-based smoothed finite element method[J]. Computer Methods in Applied Mechanics and Engineering, 2018, 331: 675-700. doi: 10.1016/j.cma.2017.11.022

|

| [21] |

BIE Y H, LIU Z M, YANG H, et al. Abaqus implementation of dual peridynamics for brittle fracture[J]. Computer Methods in Applied Mechanics and Engineering, 2020, 372: 113398. doi: 10.1016/j.cma.2020.113398

|

| [22] |

章青, 郁杨天, 顾鑫. 近场动力学与有限元的混合建模方法[J]. 计算力学学报, 2016, 33(4): 441-448.ZHANG Qing, YU Yangtian, GU Xin. Hybrid modeling methods of peridynamics and finite element method[J]. Chinese Journal of Computational Mechanics, 2016, 33(4): 441-448. (in Chinese)

|

| [23] |

史鑫, 赵剑宁, 杨苗苗, 等. 含高温度梯度及接触热阻非线性热力耦合问题的谱元法[J]. 力学学报, 2022, 54(7): 1960-1969.SHI Xin, ZHAO Jianning, YANG Miaomiao, et al. Spectral element method for nonlinear thermomechanical coupling problems with high temperature gradient and thermal contact resistance[J]. Chinese Journal of Theoretical and Applied Mechanics, 2022, 54(7): 1960-1969. (in Chinese)

|

| [24] |

孔祥谦. 热应力有限单元法分析[M]. 上海: 上海交通大学出版社, 1999.KONG Xiangqian. Thermal Stress Analysis by Finite Element Method[M]. Shanghai: Shanghai Jiao Tong University Press, 1999. (in Chinese)

|

| [25] |

王勖成. 有限单元法[M]. 北京: 清华大学出版社, 2003.WANG Maocheng. Finite Element Method[M]. Beijing: Tsinghua University Press, 2003. (in Chinese)

|

| [26] |

MADENCI E, OTERKUS E. Peridynamic Theory and Its Applications[M]. New York: Springer, 2014.

|

| [27] |

WANG Y T, ZHOU X P, KOU M M. A coupled thermo-mechanical bond-based peridynamics for simulating thermal cracking in rocks[J]. International Journal of Fracture, 2018, 211: 13-42. doi: 10.1007/s10704-018-0273-z

|

| [28] |

SHAO Y F, LIU B Y, WANG X H, et al. Crack propagation speed in ceramic during quenching[J]. Journal of the European Ceramic Society, 2018, 38: 2879-2885. doi: 10.1016/j.jeurceramsoc.2018.02.028

|

下载:

下载:

渝公网安备50010802005915号

渝公网安备50010802005915号